While there have been many advances in recent years, blown fiber cable is not a new technology, although it is relatively new compared to conventional cabling methods that date back to Alexander Graham Bell. But, even if the air-blown technology offers many indisputable advantages, there are applications where traditional cabling may be the better option. Here I explain why.

Blown fiber cables enter the market

The earliest known version of blown fiber cable (using compressed air to push fiber cabling through tubes) is found back in the 1980’s. The technique of installing flexible and lightweight fiber optic units using compressed air was further developed by British Telecom. These systems are installed in many environments – from fiber-to-the-home (FTTH) to hospitality to healthcare and to enterprise campuses. Previously, blown cable had a niche in special environments, but today they are gaining popularity due to significant advantages over conventional fiber optic cabling.

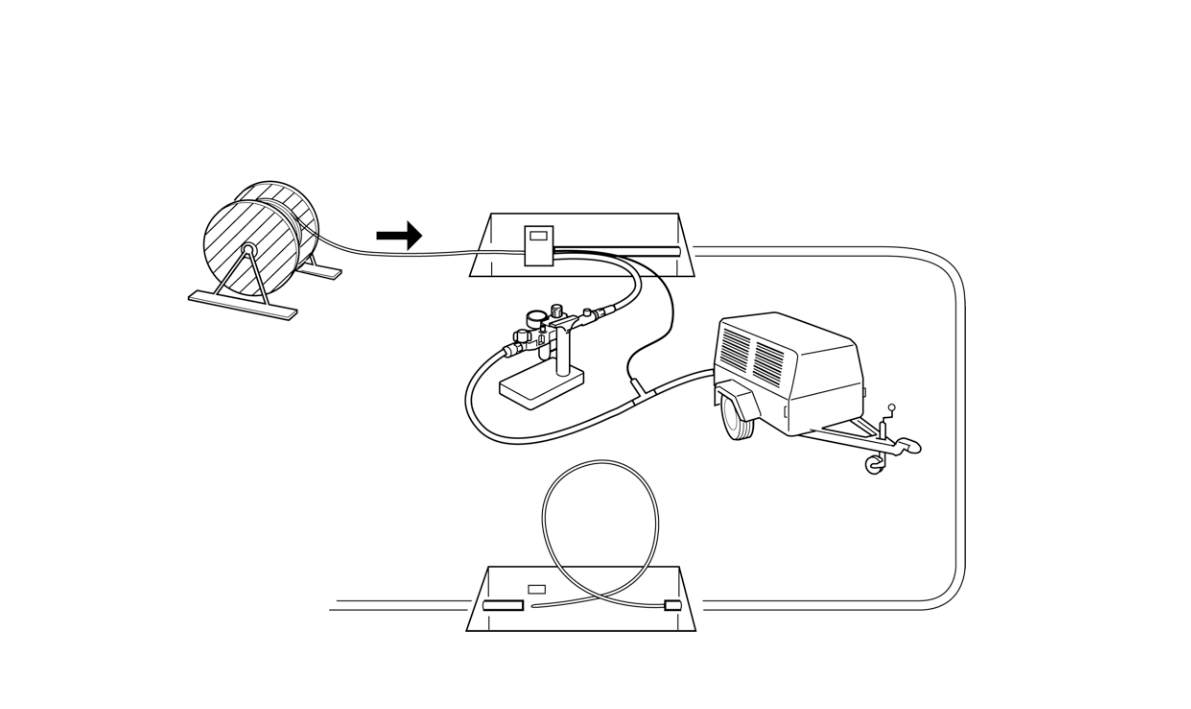

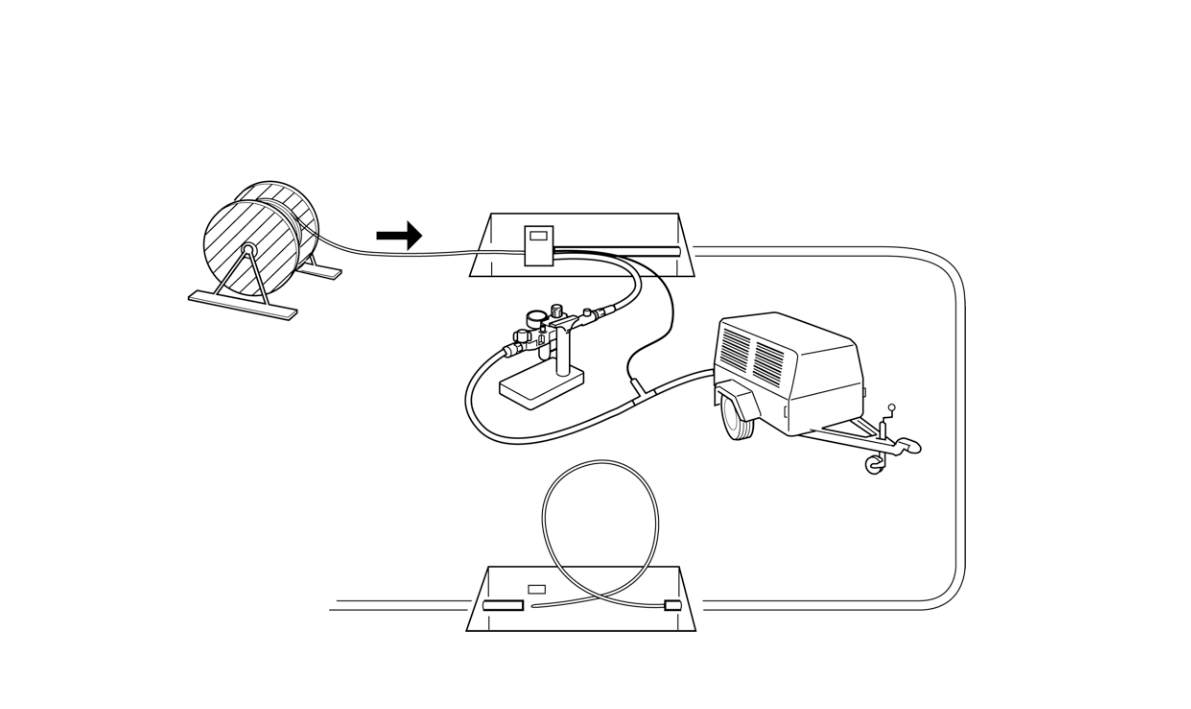

In comparison with traditional cabling techniques such as direct installed cables or cables pulled in conduits, air blown cabling utilizes small microtubes or microducts to blow (or “jet”) lightweight optical fiber bundles or micro cables through predefined routes at rates up to 500 feet per minute (150 m/min). The micro tubes are manufactured of tough, flexible materials and bundled in groupings of up to 24 units within a conduit that can be installed above ground aerially or underground or even within the building.

What is the point?

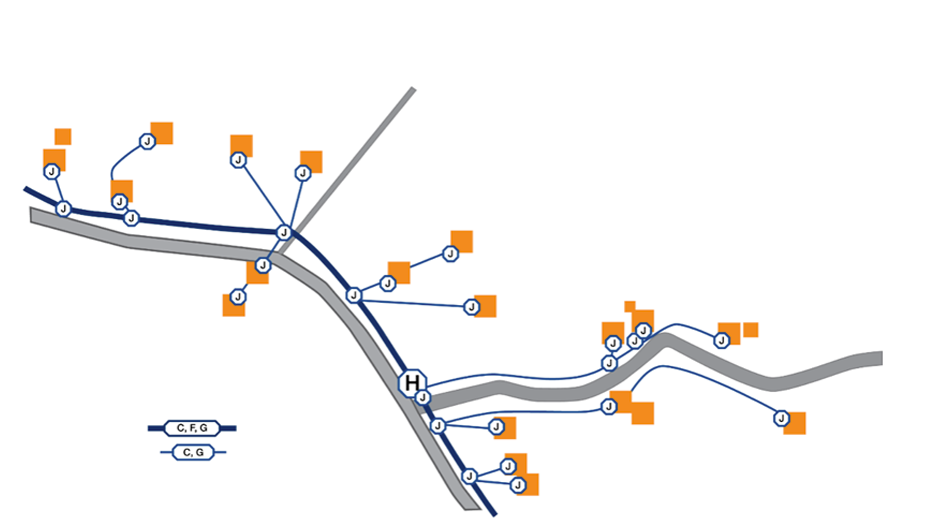

So, what is the point of first laying pipes in the ground and then blow in the fiber cables? It seems to be a two-step operation instead of just laying the cables directly into the ground. To understand this, we need to understand how these tubes are installed. These tube bundles contain color-coded cells or microducts through which the optical fiber bundles are blown. Using couplers, installers connect individual micro cable cells together in tube distribution points, to provide routes through which fiber is blown to achieve a splice-free, point-to-point installation. A splice-free installation saves installation time and improves overall system reliability, which further is enhanced because no strain is placed on the fiber during the installation process.

However, there are more into this. The ducts are installed separately and in advance, which means:

- Installation of optical fiber may be incremental, adapted to growth in end user demand.

- Unlike traditional cable pulling, the blown-in fiber is not affected by harsh treatment during installation.

- Minimization of splice points, which reduces installation time.

- Easy network upgrade with more fiber or other types of fiber.

- Simplified network design.

The benefits

Blown micro fiber cable technology offers great benefits for quick and easy incremental installations of cables. The capacity of the network can quickly be increased by inserting new cables in spare microducts when needed. The system also minimizes the number of fiber splice joints in the network compared to traditional cable solutions. The blown fiber technique guarantees high performance and reliability.

Where to use blow fiber

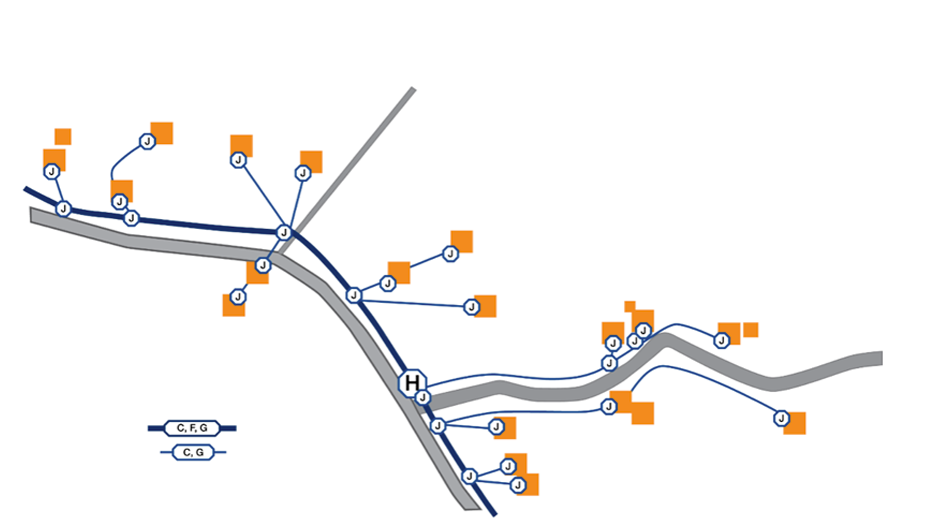

FTTH - Blown micro fiber cable systems are fast becoming the preferred system of choice in access networks, where cost of homes passed, speed of deployment, flexibility, and future scalability is of utmost importance. Today, blown fiber to the home is being adopted as the preferred architecture for access networks -- AKA the “last mile” – delivering telecommunications service to end-user’s premises.

Datacenters and 5G - Another not so obvious application of air blown technologies is for datacenter, 5G or other networks requiring high fiber count connections between two points. Sometimes several 1000-s of fibers are required and by using multiple cables blown into micro tubes, the installation will be faster and safer. It is also easier to build a redundant network.

Note that blown fiber and micro tubes are equally suitable for outdoor use as well as indoor use. For indoor applications, flame retardant micro tubes are used.

Where to use traditional cabling

Trunk Networks - When reading this post, you may make the conclusion that traditional cabling techniques should be avoided in all situations. However, there are situations where traditional cabling solutions have their place. In networks with no or few branches, such as trunk networks, the benefits with micro pipes and splice-free blown fiber installation gets less obvious.

Submarine installations - Even though there are solutions for blowing fibers under water, long distance submarine cables offer the strength and durability that is required.

Conclusion

To conclude, every installer or network owner should strive for lowest Total Cost of Ownership, TCO. Air blown cabling techniques were developed to minimize the TCO for branched networks such as FTTH. Recently, the technology has gained more interest in other applications too, such as datacenters, Internet of Things (IoT) and 5G. However, traditional cabling techniques are still the choice for long distance trunk networks.

Learn more about FTTH technologies and business from our experts.

This article was originally published in January 2021 and has been updated with minor edits.