Why is it important to raise awareness about the carbon footprint within the fiber optic cable industry? The answer is quite easy, because it matters, and there’s always room for improvement. Calculation of carbon footprint for new and existing products should be a natural part of any R&D process.

Comprehensive usage of broadband communication

To calculate the environmental impact on a specific product, like a fiber optic cable, might seem to be pointless. However, if we look into the perspective that fiber optic cables make the backbone of our modern society, enabling broadband communications to everyone and everywhere, this should definitely be a focus area. It will also be a guide for stakeholders who take sustainability seriously. Today, sustainability performance is equal to, or more important than, other parameters such as price and technical performance.

Fiber optic micro cables – a small player in a huge field

Life cycle assessment calculates the environmental impacts of a product or system during its entire life cycle, including all phases from commodities extraction to waste management. When we have a clear view of the actual carbon footprint on products during their whole life cycle, product development can focus their efforts in providing new products or set of products (systems) with improved environmental properties. To assess the carbon footprint of a product, an inventory of the greenhouse gas (GHG) emissions from all the activities for the production of a product is needed. It includes, for example, energy consumption in the production line and transportation of raw materials. Commonly, international methodologies based on GHG Protocol and ISO 14064 are applied for assessing carbon emission performance.

When performing calculations on a network component such as a micro cable, you also need to calculate the effects of the whole network. For example, a certain micro cable with a slimmer design might fit into a slimmer microduct. A slimmer microduct contains less material, hence resulting in a lower carbon footprint. The slimmer cable and duct also reduce the carbon footprint from shipping and installation.

Understanding carbon footprint in the fiber cable industry

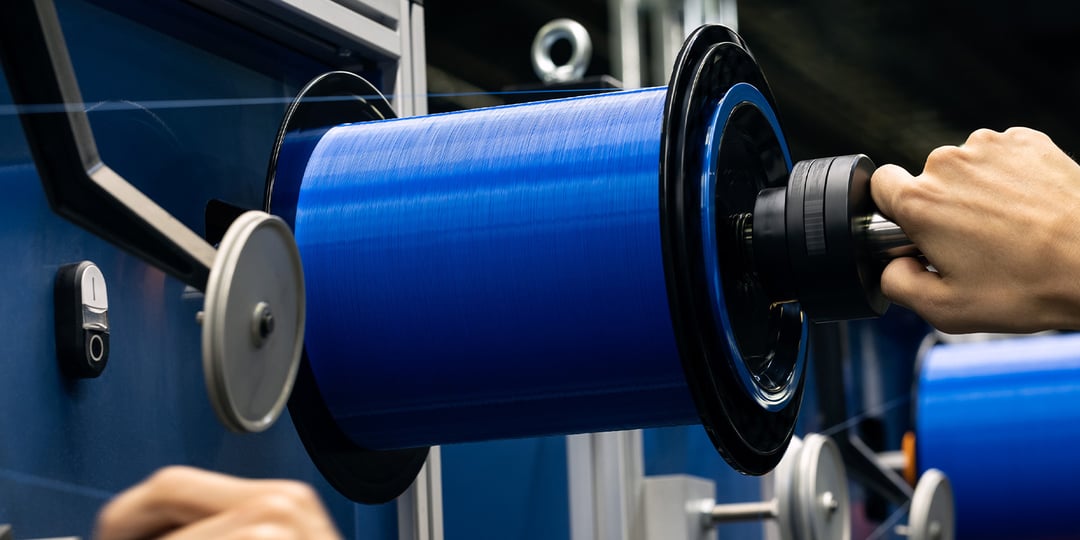

The carbon footprint of fiber optic micro cables produced by Hexatronic Cables and Interconnect Systems (Hexatronic) is always assessed. The scope of the assessments is cradle-to-gate from raw material to the finished product.

Accordingly, the research questions of the assessments are:

- What is the total carbon footprint of a micro cable?

- Which processes have substantial contributions to the total carbon footprint?

- What are improvement strategies and mitigation measures?

Are you interested in finding out what a carbon footprint assessment of a micro cable looks like? Contact Hexatronic for details. Welcome to join the journey towards a low carbon footprint for fiber optic networks!

This blog post was originally published in December 2021, but has been updated with additional insights.