As the fiber optic industry evolves, cables get slimmer or more densely packed with fibers. In this article, we investigate reasons to go for slimmer products for your project, and ask ourselves, is slim always good?

Fiber optic product developers rise to the challenge of designing slimmer cables while adding maximum capacity. It is a challenging task, but there have recently been break-troughs. Check out the news about the world's slimmest 24 fiber air-blown solution here.

Less material used

Using less of the same material to create a product is always better for the environment. For a slimmer cable, production needs less material. And when you match your slim cable with a slim duct, production needs much less material. But it is in transportation and handling you can see the most significant changes.

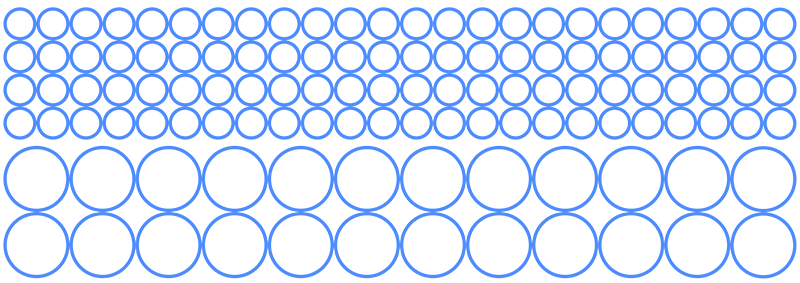

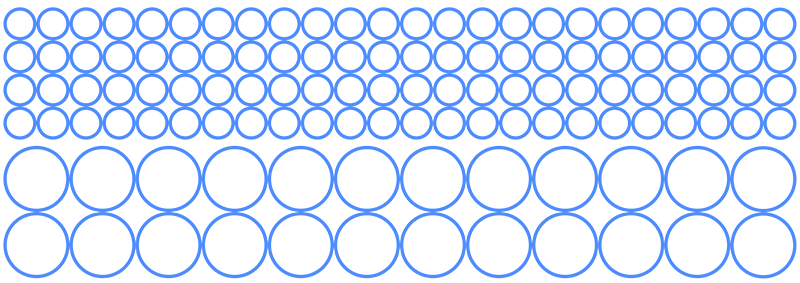

For example, if you use an air-blown cable instead of a micro cable, you can choose a duct with 7 mm in diameter instead of, say, 14 to 16 mm. It might not seem like a big deal, but the difference is evident when you observe the ducts in a cross-section. In a simple illustration, you can see that the volume is decreased by 4. Figure 1 shows how 48 ducts with 7 mm in diameter replace the same volume as 12 with 14 mm in diameter.

Duct drums can also be smaller, and you can fit more drums during transport. Handling large drums of duct or cable can be demanding, but operating the gear becomes much easier when you go for the slimmer options.

Figure 1

Increasing capacity

Another advantage of super-slim fiber optic cables with a maximized number of fibers is the possibility of upgrading existing networks. Ducts are already in the ground, and with the slim air-blown options, you can share the pipes in the current infrastructure. When building a new housing area, you commonly go for the most cost-effective infrastructure, covering the needs of today without considering future expansion. When new sites pop up in the neighborhood, upgrading existing feeder and distribution networks with more capacity could be highly beneficial instead of digging new ditches. Also, drop networks (e.g., end-user connections) can benefit from a capacity upgrade when a company grows over time.

Slim is not enough

Even though air-blown fiber has been around since the 80s, it has not always been as good as today. The products have certainly improved in quality during the last decades. Air-blown cables used to be fragile and did not withstand water and ice very well.

Today, cables are more flexible and suited to harsh conditions. The protecting sheath has a vital role here. Different layers contribute to the overall character of the fiber optic cable. Soft layers make it more flexible, hard coatings protect it from dents, and the surface characteristics make the installation easier. Plenty of tests verify the usability and performance of the cable. A super slim cable with 24 fibers is of little use if the installation process is a hustle. To find the best possible option, comparing specifications like bend radius and blowing distance can be helpful.

Conclusion

In conclusion, recent leaps in product development have extended the possibilities of slim air-blown cables. Nowadays, super slim cables can contain up to 24 fibers which can be useful in many projects. Reducing the duct size with a slimmer cable can provide savings in both material and transportation. Super slim cables, containing more fibers than before, can also be blown into existing ducts to expand network capacity or reach new areas without digging. However, it is crucial to take a closer look at the specifications. Simply being slim is not always good. The solution you choose needs to fulfill your requirements for installation ease and be compatible with the conditions at your site.

This article was originally published in October 2022 and has been updated with minor edits.